Prior to anything else, I'd like to share some information about my previous work experience and qualifications. As a rookie, I was in charge of the development and production of surface treatment products that were both mechanical and chemical in nature when I started my first job. We were mass-producing castings at the time, and they had the option of having a protective anodized surface treatment applied to them as well. Given the significant differences in aluminum extrusion, forging, and stamping that die casting compact material displays, as well as the fact that die casting compact material has a relatively high silicon content, die castings will not be anodized in the vast majority of cases. Floating ash is expected to accumulate on the anode surface after anodizing, which will have a negative impact on the surface quality of the anode, particularly when using die-casting aluminum adc10 and ADC12 of aluminum silicon copper alloy, both of which are Japanese brands. GB/T 15115-2009, a Chinese executive standard, identifies ADC12 as being equivalent to the Chinese alloy code yl113 and the Chinese alloy brand yzalsi11cu3, both of which are produced in China. Another alloy code that is equivalent to yl113 is ADC12, which is manufactured in China and has the designation ADC12 as well.384 is a trademark that is used to identify aluminum alloy aluminum die casting castings that are manufactured in the United States of America. Specifically, the executive standard is ASTM B 85-03 Standard Specification for Aluminum Alloy Die Castings, which is an abbreviation of the American Society for Testing and Materials (ASTM).

At the time, efforts were being made to improve the anodizing process for ADC12 die castings, which was the subject of ongoing research and development. Water was treated with HF hydrofluoric acid during the pretreatment process in order to remove silicon from it. Anodizing is almost complete, and we're on the verge of completing the process. Wearing this item is extremely uncomfortable as a result of the matte finish, dark color, and slight yellow tint to the black. Furthermore, anodizing is not recommended for this application due to the poor wear resistance and corrosion resistance of the anode layer of the die casting in question.

It is important to note that because die cast aluminum adc6 is made from an aluminum magnesium alloy, it will be much easier to anodize and the appearance effect of surface treatment will be much better than that of ADC12 because its silicon content is typically less than 1.0%. cnc machining parts cnc machining services adc6 will be much easier to anodize and the appearance effect of surface treatment will be much better than that of ADC12. When compared to die cast aluminum ADC12, die cast aluminum ADC6 will be much easier to anodize and the appearance effect of surface treatment will be much better. Wear resistance, corrosion resistance, and weather resistance are among the properties of the anode layer that can be improved by using hard anodizing treatment to improve the reliability and quality of the anode layer. Other properties that can be improved include corrosion resistance, wear resistance, and weather resistance. Anodic pretreatment is the process of removing ash from water before it enters the treatment process. Hydrofluoric acid is used in this process. This agent, which is composed of monoacid sulfuric acid, is used in the anodic oxidation tank to promote oxidation. It was decided to use a low temperature and high pressure in this experiment, with the film thickness being set to at least 100um. It is necessary to perform frequent dosing maintenance and bath reconstruction on the liquid contained within the anodic oxidation tank in order to ensure proper operation.

According to my observations, many manufacturers should come to the conclusion that die-casting aluminum is not suitable for anodizing when they conduct surface treatment on various aluminum materials. A number of factors influence these characteristics, including the chemical composition of die-cast aluminum and the characteristics of the electrophoretic anodizing process (see below). If that is the case, what makes die-cast aluminum unsuitable for anodizing in the first place?

To achieve uniformity and flatness in the anodized film, it is necessary for the process to be successful that the aluminum surface is free of impurities and that the aluminum material is relatively pure, and this can only be accomplished by using anodized aluminum. Extremely high concentrations of impurities and other components are almost certain to have an effect on the thickness of the film formed during anodic oxidation, and it is possible that it will have a direct effect on whether or not the film forms at all during anodic oxidation. Primarily due to the fact that other metal elements have the potential to directly alter the color of the formed aluminum anodized film, dyeing after anodizing has been designated as a capital offense and is punishable by death immediately after the process begins.

The majority of aluminum alloys that are cast in molds or die cast have a high silicon content, which is a result of the method of casting. If you are using ht412 special ash remover for die casting aluminum, the anodic oxide film may still be dark after die casting aluminum, making it difficult to obtain a colorless and transparent oxide film after the die casting process. Anodic oxide films change in color from light gray to dark gray to black gray with increasing concentrations of silicon in them. The color of the film changes from light gray to dark gray to black gray with increasing concentrations of silicon in them. As a result, the cast aluminum alloy does not lend itself to the traditional method of anodizing and should be avoided.

There are, on the other hand, anodizing solutions for die cast aluminum that are available. Die casting parts can complete the structure, edges and custom die casting corners, and oxidation quality that forging parts and turning parts / CNC parts are unable to achieve. Die casting parts are also less expensive than forging parts and turning parts. Moreover, die casting parts are less expensive than forging and turning components. Furthermore, die casting components are less expensive than components made by forging or turning. At all times, a strong emphasis must be placed on the quality of the die castings. The ability of the process to control minor adjustments and minor details is what determines the overall quality of the anode in terms of overall performance and performance characteristics.

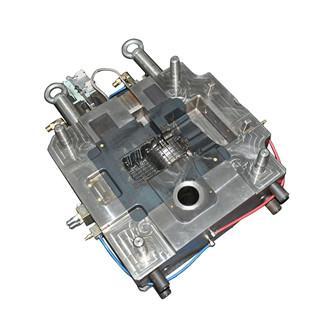

Heating die casting dies is a type of machine that is used to accomplish this task precisely.

Temperature control equipment for aluminum alloy die casting dies is a relatively new type of temperature control equipment in the field of environmental protection. It is a new type of temperature control equipment in the field of environmental protection that is being introduced. Although it is intended for use in the die casting industry as a whole, it is not restricted to use in the die casting industry alone. The machine is equipped with a high-temperature-resistant heat transfer oil (water) circulation pump, a heater, a control system, pipelines, and a support frame to ensure that the mold temperature remains stable throughout the process. A sufficient cooling system is required for the proper operation of the special mold temperature machine with cooling demand in order for it to be a safe and reliable machine.

It is the goal of the machine for heating or cooling Aluminum Alloy Die Casting Die Temperatures to heat or cool the die and keep it at its working temperature, as well as to ensure the consistency of die casting quality and to reduce the processing time for Aluminum Alloy Die Casting Die Temperatures. In the die casting industry, the temperature of the die has a significant impact on the quality and timeliness of the die castings produced. Die-warming machines, which are used to warm die-cast components before they are cast, can help you achieve higher overall quality in your finished product when die casting aluminum-casting components.

Maintaining temperature control of the die during the die casting process is critical to ensuring high quality die castings. It is necessary to preheat the die prior to casting in order to achieve the best results from die casting. A die-casting die warmer is used to accomplish this. In order for dies made of different die-casting alloy materials to function properly, the surface temperature of the dies must be maintained at a different temperature from one another. The typical temperature ranges for zinc alloys are 170 to 220 degrees Celsius, whereas the typical temperature ranges for aluminum alloys are 220 to 260 degrees Celsius, respectively.